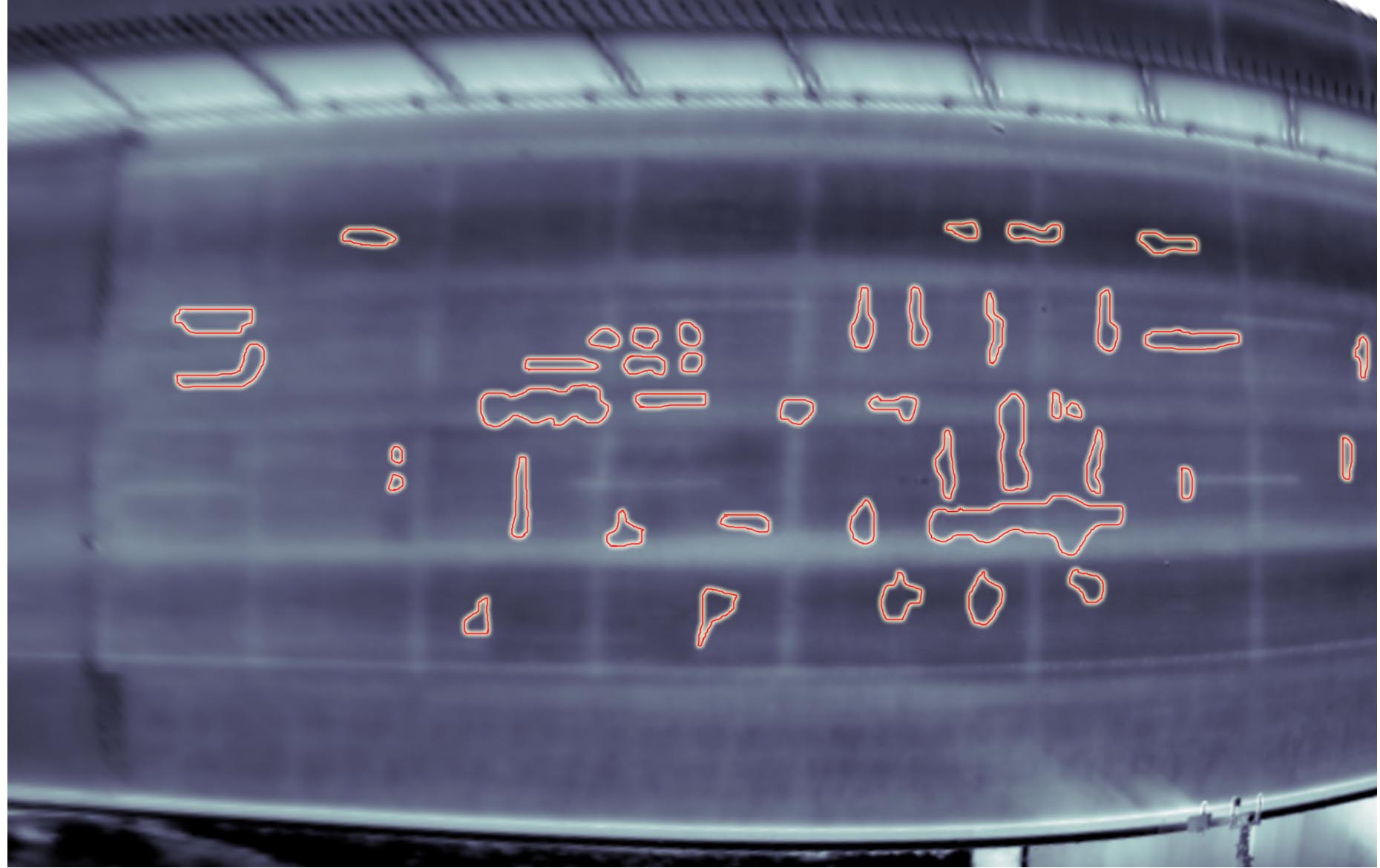

- Detects subsurface damage in concrete

- Delamination

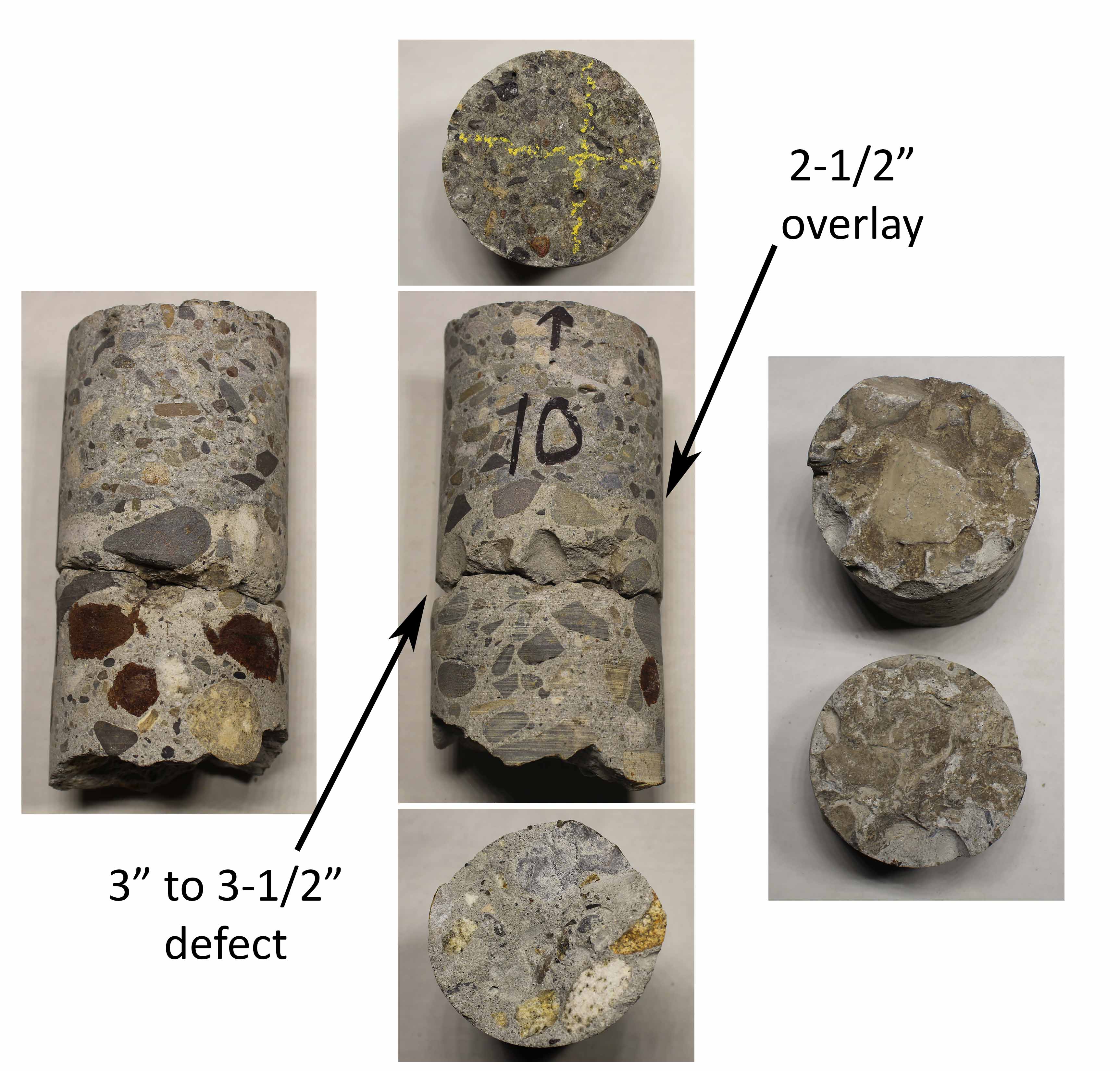

- Debonded overlays

- Subsurface voids

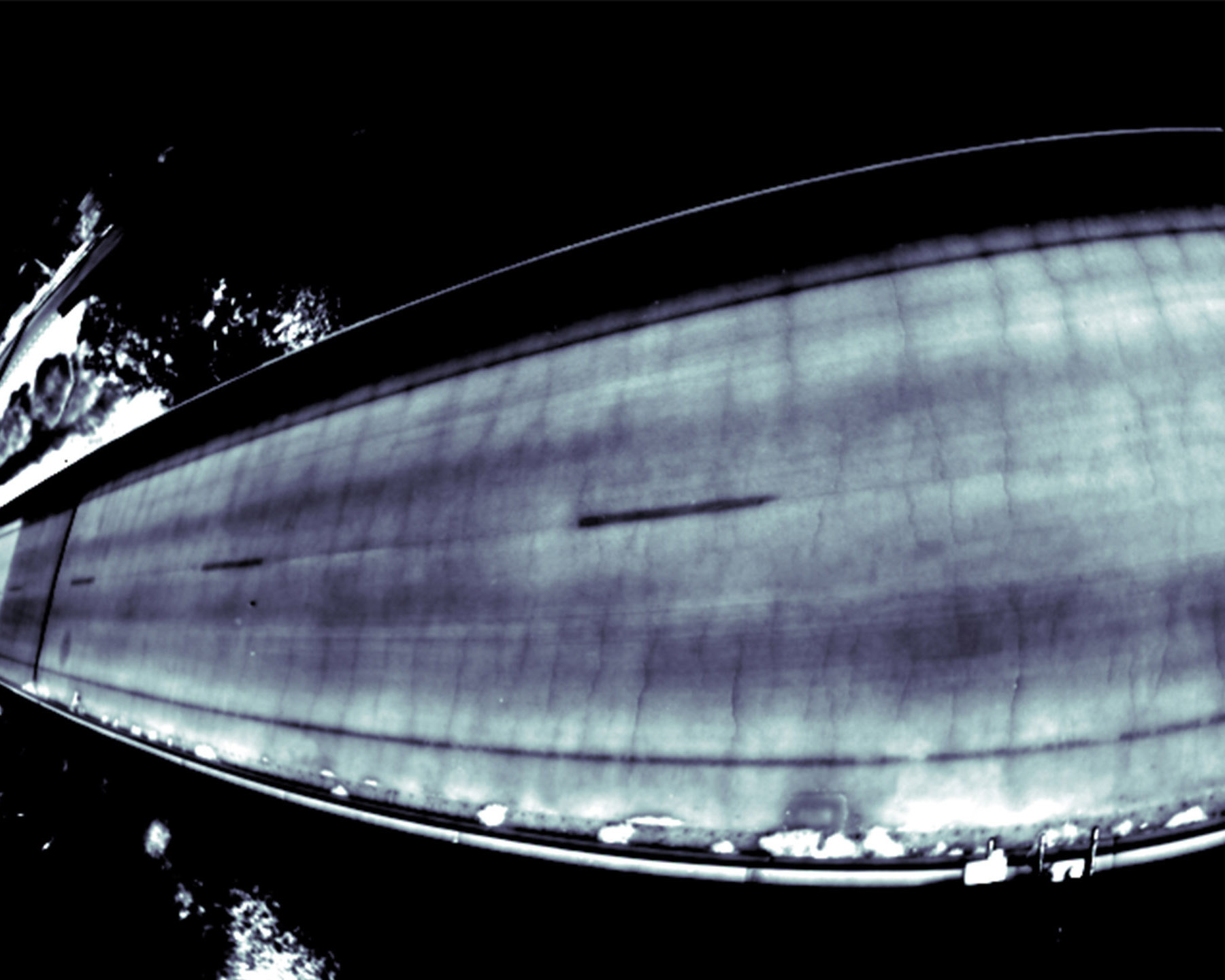

- Bridge remains open to traffic

- Non-contact remote sensing

- Produces accurate plan-view images

- Extent and location of subsurface damage

- Determine repair quantities

- Time-lapse measurements

- Overcomes limitation of conventional IR

- Environmental tolerance

- Reliable, reproducible results

|

Applications

- Bare concrete bridge decks

- Concrete and steel decks with overlays

- Tunnel linings

- Dams, piers, abutments, walls and soffits

- Thick film coatings

- Concrete foundations, chimneys and pillars

|

|

|

Rapid setup on bridges

|

Key Features

- Objective, quantitative results

- Simple to interpret images

- Highly reproducible

- 100% coverage of area inspected

- Portable, simple to operate technology

- Automated data collection and analysis

- Easy to interpret results

- Autonomous / remote operation

- Mounts on deployable masts, existing structures or other features

- Minimal impact on operation

- Non-contact measurements from large distances

- No traffic control required

- Environmental tolerance

- Ambient weather conditions

- Inside tunnels and buildings

|

Measurements

- Subsurface delamination and voids

- Debonding of overlays and thick coatings

- Voids in concrete

- Structural features of concrete and steel structures

|  |

Detect defects through overlays

|

Measure with live traffic

|

| |